ERT250

Benefits of Edge Roller Technology (ERT) 250 Conveyor

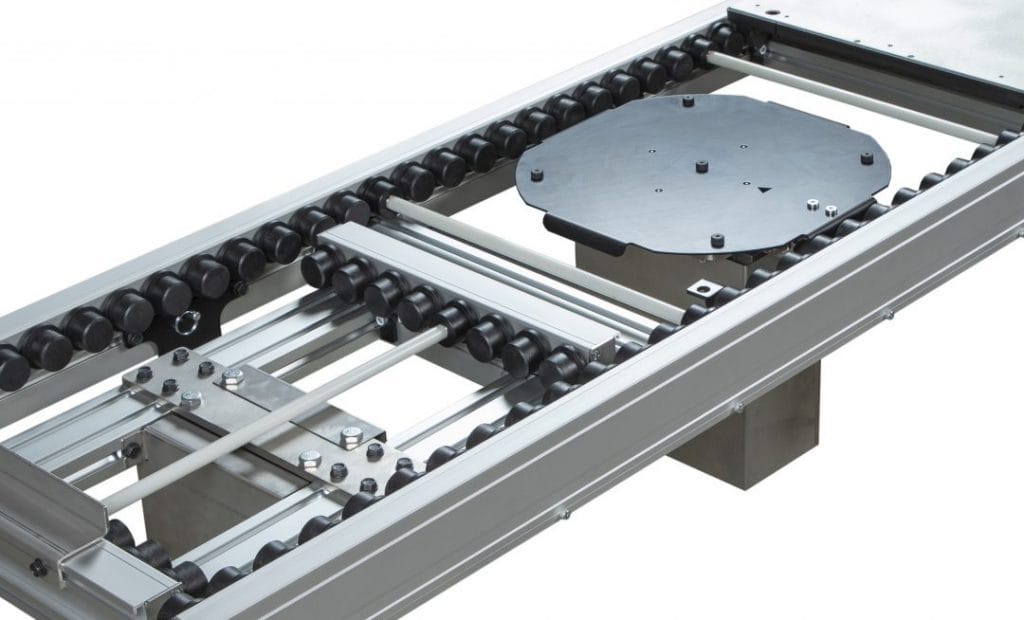

Our precision edge roller pallet and tray handling conveyors provide efficient, non-contact zoning for medium & heavy load assembly automation applications. They feature a clean, open roller design and are ISO Class 4 verified* for cleanrooms.

*To verify clean room requirements, an unloaded base conveyor was tested and did not generate particulate that would be beyond the specified standards. However, the verification does not provide assurance that any or all applications will meet this requirement. Application testing is recommended to ensure clean room standards are being met. Dorner takes no responsibility in the clean room performance of the final conveyor or application.

Best For:

- Pallet & tray handling

- No & low back pressure accumulation

- Cleanroom applications

- Large & medium assembly automation

- Medical Product Manufacturing

- Packaging

- Medical Device Manufacturing

- Automotive Assembly

- Electronic & Consumer Goods Assembly

- Appliance Manufacturing

Sizes & Measurements

- 120 mm to 960 mm wide

- 150 mm long tray minimum

- 38 mm diameter rollers on 50 mm centers

Loads & Speeds

- Loads: up to 114 kg (250 lbs) per pallet or tray

- Up to 6.8 kg (15 lbs) per roller

- Speeds: up to 37 m/min (121 ft/min)

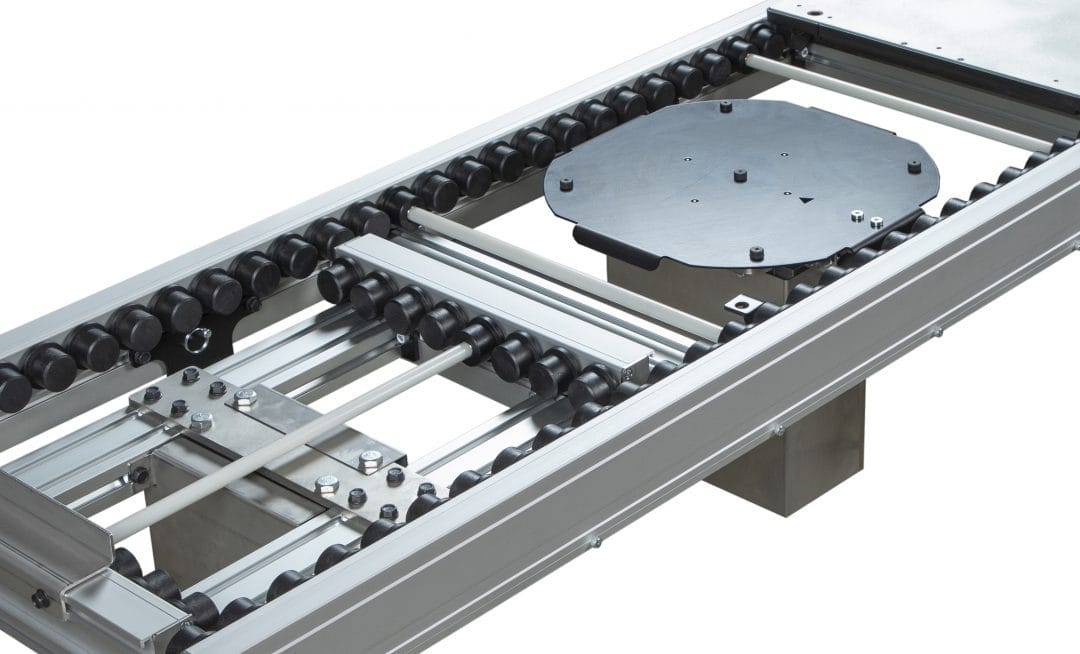

Pallets

- 320 to 800 mm pallets

- Static conductive HPDE skirt

- Proximity sensor pick-up on side and bottom

- Optional pin tracking ball bearings for corner conveyors

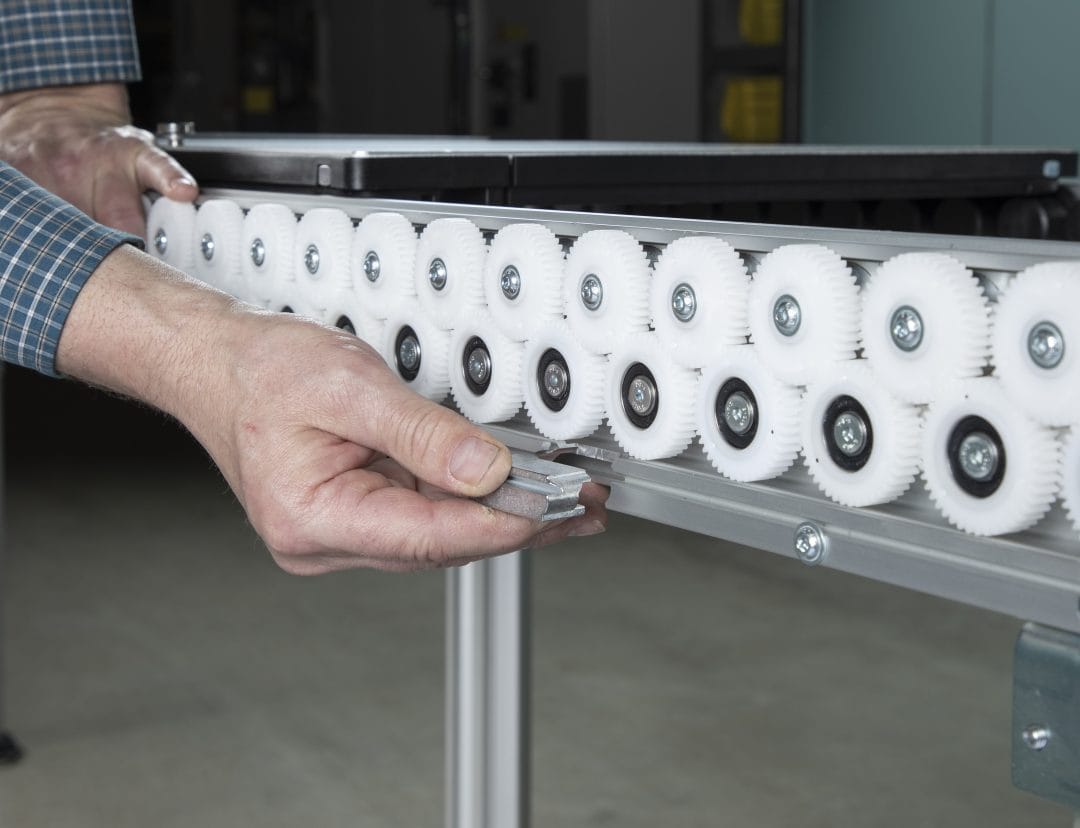

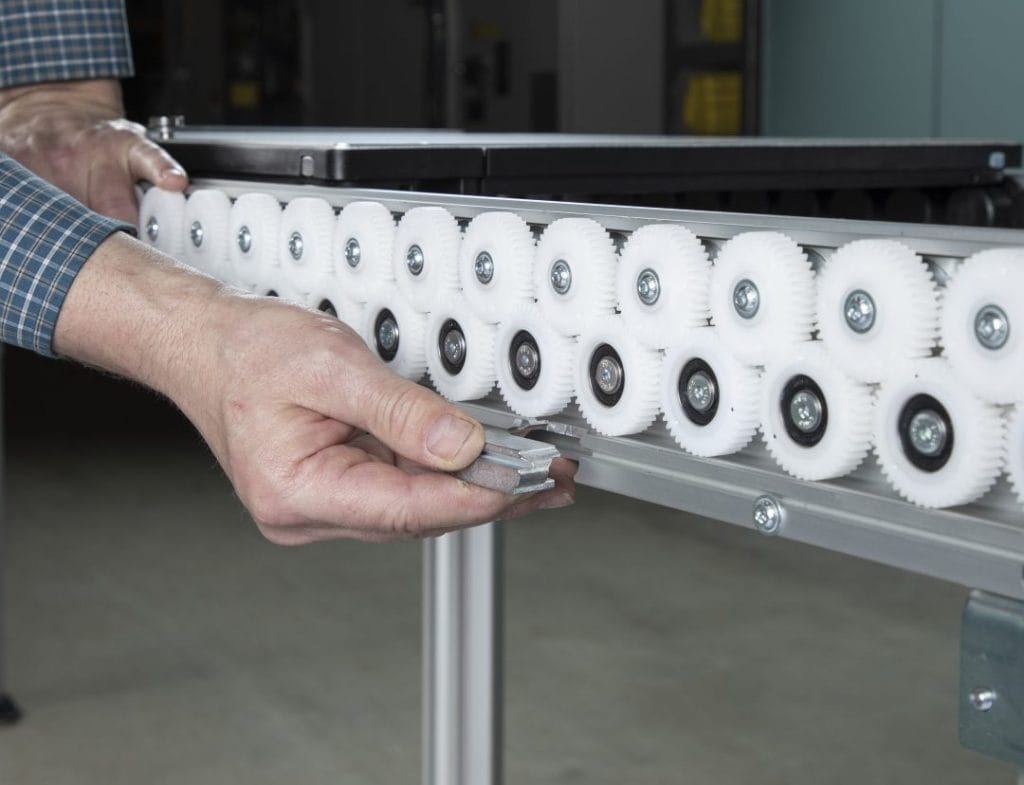

Zone & Slip Roller Technology

- Non-contact zone control eliminates pallet stops and costly pneumatic valves

- Low back pressure slip rollers can be used for full length with conventional pneumatic pallet stops

- Individual rollers can be replaced without affecting the remaining portion of the conveyor

Easily Reconfigurable

- Gears, drive shaft, and gearmotor can be repositioned in the field

- Lower gears can be removed and gearmotor added to create new zones

- The drive shaft can be moved to any roller zone and relocated to the lower height for added product clearance

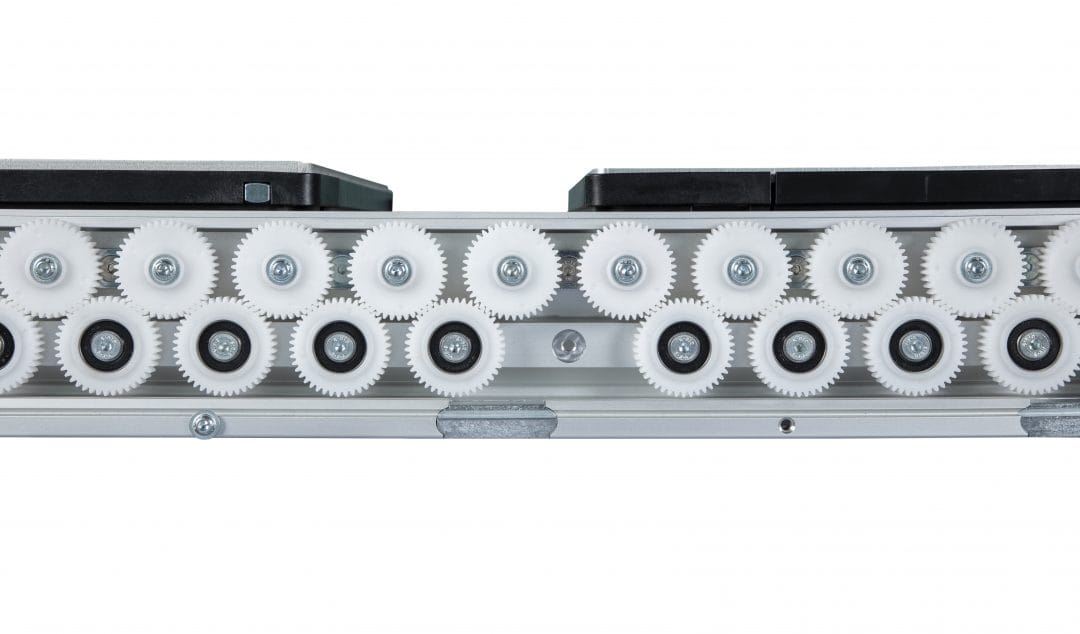

Patent Pending Gearbox Drive Design

- Durable, linear gearbox design provides a robust and flexible method of driven rollers

- Reversible motors for assembly automation

- 50 watt, 3.5 amp, low voltage brushless DC motors save space and provide improved efficiency

- All motor controllers are Ethernet IP, Modbus TCP or PROFINET for easy of control logic, wiring and communication

- Accessories

- Engineered Solutions

- Gearmotors & Controllers

- Support Stands

- Pallet Stops

- Manuals & Literature

Accessories

Engineered Solutions

Gearmotors & Controllers

Support Stands

Pallet Stops

Manuals & Literature

Looking for Service Manuals? Search for Service Manuals by part number or product type HERE.

| Literature | Pages | File Size |

| ERT250 Brochure | 4 | 3.9 MB |

| Engineering Manual | Pages | File Size |

| ERT250 Engineering Manual | 48 | 14.8 MB |